Double-sided tissue tapes are a type of pressure-sensitive tapes that need only sufficient pressure to stick on a clean and flat surface. Such tapes are a part of the range of specialty tapes that serve special adhesive purposes. Hence, they have a wide range of applications beyond just packaging and sealing.

What is Double-Sided Tissue Tape?

Double-sided tissue tape is an adhesive tape having glue on both sides of the tissue and one side having a peel-off liner sheet. The tissue acts as a carrier in this specialty tape. The adhesive of double-sided tissue tape can be rubber-based, solvent-based adhesive, acrylic adhesive, or another hot melt adhesive.

The common size of the double-sided tissue tapes ranges from 0.5 inches to 6 inches in width and 10 meters to 50 meters in length.

How is Double-Sided Tissue Tape Made?

The commercial production of double-sided tissue tape includes the following steps:

1. Preparing the Tissue Liner

The first step includes the production of tissue paper on the double-sided tape. For that, the machine processes wood pulp into thin and lightweight sheets. It then bleaches, compresses and dries that into thin sheets of tissue paper. Then, it slices the sheets as per the required size for the jumbo rolls of double-sided tissue tapes.

2. Preparing the Adhesive

To prepare the adhesive, the selection of the right polymer is crucial. There are different types of polymers like silicone, acrylic, rubber-based etc. After selecting the polymer, tackifiers are added to adhesive polymers to improve their stickiness.

Then, plasticizers are added to the mixture to increase the thickness (viscosity) of the adhesive. Other ingredients like stabilizers can be also added as per the requirement to increase the durability and stability of the adhesive.

3. Coating the Adhesive

After preparing the right adhesive, it is coated onto one side of the tissue liner and left to be dried. To activate the pressure-sensitive adhesive, the adhesive is placed into the oven or any drying chamber like an autoclave. Otherwise, the adhesive is exposed to infrared radiation which helps in evaporating the solvent and subsequently activates the adhesiveness.

4. Sandwiching the Adhesive Tape

This process involves sandwiching the tissue layer with adhesive layers on both sides. For that, the opposite surface of the tissue paper that contains adhesive is covered with another layer of adhesive, hence sandwiching the tissue layer between adhesive layers.

5. Rolling and Spooling

Then the sandwiched layers are wrapped around large kraft liners or paper spools. As the tapes are in the jumbo rolls in this state, they are placed onto jumbo cutters which are programmed to cut the whole jumbo rolls into equally smaller rolls. The cutting sizes can be adjusted in the cutting machines as required.

6. Applying the Release Liner

At this stage, a non-sticky paper – generally made of silicone – is applied on one side of the tape. This is to smoothen the handling process. Also, it prevents tampering with the adhesive quality by creating a barrier between the adhesive layer and the layer of contact. Once the applicator is ready to use the tape, he can simply remove the silicone-based release liner and paste the tape on the surface.

7. Checking and Testing

During production and post-production, the adhesive and the tape go through a series of tests to check the quality of the tape. Every time, the tape or adhesive goes through a test, we record all data in technical data sheets. Here are some parameters that we check during these tests:

a. Adhesion Strength

This test determines the strength of the adhesion – the overall bonding capability of the tape. We apply tape to different surfaces to check the strength and then remove it from different angles. In this test, the angle we used to peel, the force exerted to peel and the time taken by tape to peel off are recorded. To calculate the adhesive strength, we divide the force exerted to peel by the width of the tape.

Mathematically, the formula is,

Adhesion strength = Force (Newton) / Width of tape (inches or mm)

b. Peel Adhesion

This test measures the force required to peel the different samples of the same tape. For that, we choose random sizes of double-sided tissue tapes to apply on different surfaces and then peel them off at different angles. Then we record the time taken to peel off and the force required to do so.

c. Tack Quality

Tackiness is the ability of the tape or adhesive to stick to the surface. To test the tackiness of the tape, we use a standard probe to press onto the surface of the tape. Later we measure the force required to separate the probe from the surface.

d. Shear Strength

The ability of an adhesive tape to handle the load without splitting apart is called shear strength.

To measure the shear strength, we cut the adhesive tape to a suitable length. Then we apply one end of the tape to the suspended bar of testing equipment and the second end to the weight bars. Later, we change weight periodically to check the point where the tape is splitting or shearing apart.

e. Temperature Resistance

Temperature greatly affects the adhesive strength of any tape. Extreme temperatures can temper the chemical and physical properties of the adhesive. So, it is difficult to work with such tapes that cannot resist extreme temperatures.

Therefore, we test our double-sided tissue tapes under a wide range of temperatures.

f. Aging Test

This test determines the age or longevity of the double-sided tissue tape. We keep different samples of double-sided tissue tapes under different variables like temperature, moisture, sunlight etc to model a real-world scenario. Then we check its adhesive strength after some time to identify whether these agents have affected the adhesiveness, hence checking the age of the tape.

g. Dimensional Stability

This test determines whether tape shrinks or stretches under different storage conditions. We carefully monitor the sizes before and after the storage period to note any differences.

Types of Double-Sided Tapes

You can find various types of double-sided tapes that offer special features and applications. Some common types are;

1. Double-Sided Tissue Tape

This type has a tissue layer as a carrier between hot melt adhesive layers from both sides.

2. Double-Sided Cloth Tape

These tapes, often called carpet tape, use cloth as a carrier of adhesive. The adhesive layers cover the cloth carrier from both sides.

3. Double-Sided Acrylic Tape

In this tape, acrylic foam is the carrier. The acrylic adhesive covers the carrier from both sides.

4. Double-Sided Foam Tape

This tape uses polyethylene or polyurethane foam sandwiched between adhesive layers. The adhesive of this tape can be from rubber, any solvent or from acrylic.

5. Double-Sided Transfer Tape

This special application of double-sided tape consists of a thin layer of adhesive covered with a liner on top. This tape doesn’t contain any carrier layer.

6. Double-Sided Film Tape

It consists of a polyester or polypropylene carrier sandwiched between adhesive layers.

7. Double-Sided PET Tape

This tape uses Polyethylene Terephthalate (PET) as a carrier with layers of adhesive on both sides.

What Is The Best Permanent Double-Sided Tape?

The best permanent double-sided tape depends on the application you are using it for. Each type of double-sided tape has its unique purpose. Therefore, before selecting the right type of double-sided tape, you must understand the surfaces you want to join or mount together.

Here are quick pointers you need to know before you select the best permanent double-sided tape for your purpose:

- Tissue tape is ideal for lightweight mounting

- Cloth tape is ideal for securing carpets, cables, rugs, and for temporary repairs of similar surfaces

- Acrylic tape is ideal for mounting in extreme weather conditions

- Foam tape works well for dampening, cushioning or for mounting two uneven surfaces together

- Transfer tape is suitable for heavy-duty projects that do not need carrier layer

- Film tape is perfect for mounting and sealing work under moisture and chemical exposure

- Double-sided PET tape is famous for bonding applications in automotive, electronics and manufacturing industries

Features Of Double-Sided Tissue Tape

- High tack

- Immediate bonding capability

- Resistance to solvent, moisture and chemicals

- Can withstand extreme temperature

- Offers relaxation properties

- Quick bonding with surfaces like metals, paper, plastics etc

- Cost-effective

- Easy to use

- Easy to tear by hand

What Is Double-Sided Tissue Tape Used For?

Some common uses of double-sided tissue tape are

- Mounting lightweight objects together, like in the paper and print industry, embroidery industry and automotive industry

- Laminating lightweight material like plastic, cork, textile etc

- Splicing oils, papers or films

- Laminating and fastening usage in printing industries

- General fixing and mending

- Gift wrapping

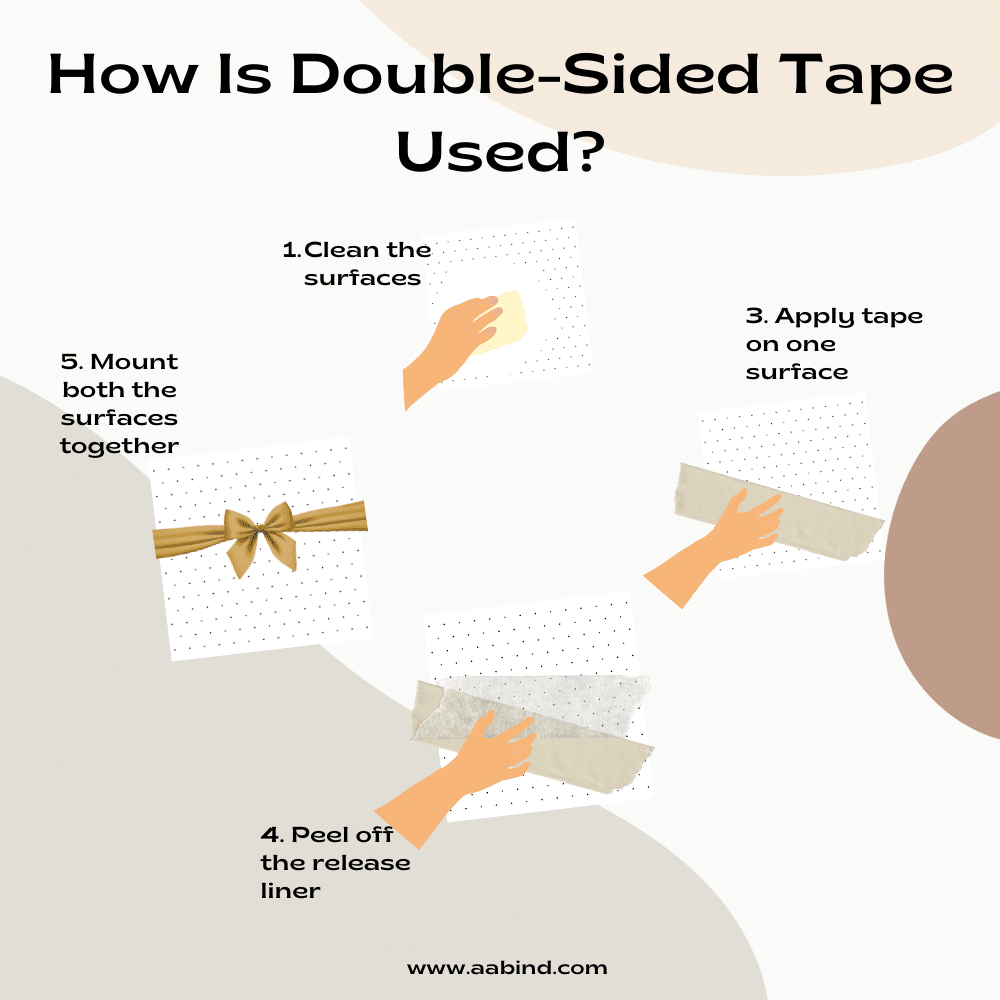

How Is Double-Sided Tape Used?

Using double-sided tissue tape is quick and convenient. It is easy to tear by hand and needs no scissors or tape dispenser. Here how to use double-sided tissue tape:

- Clean the surfaces where you are going to apply the tape

- Make sure both surfaces are smooth and even

- Apply one side of the double-sided tissue tape on one of the surfaces and tear by hand

- Peel off the silicone-based release liner from the other side of the tape

- Mount the second surface on the other side of the double-sided tissue tape

How Do You Remove Double-Sided Tissue Tape?

Double-sided tissue tape is one of the most convenient and mess-free adhesive tapes to work with. In case, you want to remove the double-sided tissue tape from any surface, you can easily remove it without getting any residue.

Just part away the surfaces that you mounted together using double-sided tissue tape. Now to remove the tape from the second surface, gently peel off the tape from one of its ends and pull it back with a certain angle.

Range of Double-Sided Tissue Tape Manufactured by AAB Industries LLC

AAB Industries LLC specialises in manufacturing a wide range of double-sided tissue tape sizes. We use state-of-the-art technology to manufacture and carefully examine the quality of the double-sided tissue tape. Here, we produce a wide range of widths and lengths for double-sided tissue tapes. Contact now to get more information about the double-sided tissue tape.