As leading Stretch Film Manufacturers in UAE, Middle East, Africa, Stretch Films are one of our fastest selling products. Stretch films are primarily used for palletizing goods and hence this product has applications in a very wide range of industries. Every Manufacturer needs this product to package their pallets before shipping them to their customers.

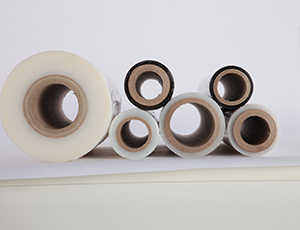

As simple as it sounds, there are a lot of variants in stretch films. We at AAB pride ourselves on having the largest range in this product line. We have a product to suit the needs of every customer. This product varies in the thickness of the film to a variety of stretch ability needed for different machines used by our customers.

As Stretch film manufacturers we have

3 Main Products

We have a range of thicknesses varying from 12 microns – 40 microns based on our client’s application and need. We also offer a variety of different grades based on stretch ability of our product. This ranges from Hand grade stretch film (150% stretch ability) to Ultra High Power Stretch (350% stretch ability). Along with the above-mentioned parameters we also have a range of colours Clear, Black and other coloured (Available on request) stretch film. This strong range in our products allows us to customize our solutions to suit every customer’s needs. This makes us a preferred partner for all our customers.

A notable product in this range is our Ultra-thin stretch film [12micron or lower], which helps us our customers save 30-40% of their costs. It is a specially developed stretch, which works just as well as the other higher thickness products but provides significantly higher yield to the customers giving them more pallets per roll and eventually saving a lot of money for the customer.

We have added an environmentally friendly Oxo-Biodegradable stretch film, which protects the environment and is also mandatory in a few countries. This film degrades in a 6-month period to avoid any environmental pollution. There are similar variants in terms of thickness and stretch ability available in this as well. A large number of environment conscious customers are moving to this particular grade.

So you get a full range of stretch films from the leading Stretch film manufacturers AAB Industries. We offer the very best prices for B2B customers and top quality on all packaging materials.

Frequently Asked Questions

What is stretch film used for?

Stretch film is mainly used for pallet wrapping and goods protection. Stretch films protect goods from moisture, sand, dirt and other contaminants.

What is the difference between stretch film and cling film?

Stretch film is used to protect goods during transportation or storage. It offers excellent puncture resistance. Whereas cling film is thin plastic made of polyethylene. It is mainly used for food wrapping.

What is the chemical composition of stretch film?

Stretch film is composed of stretchable polyethylene plastic (PE). Depending on the structure, polyethylene can be either highly dense (HDPE) or low-density polyethylene (LDPE). Other than that, some stabilizers are also used to improve the features of the stretch film like UV stabilizers, slip agents, and colourants.

What is cast stretch film used for?

Cast stretch film is mainly used for packaging, unitisation of pallets, and protection of goods during transport and storage.

What is the difference between cast and blown film extrusion?

Cast film extrusion is a process of creating plastic sheets by extruding molten plastic through a flat die, resulting in thin and flat plastic sheets. These sheets are commonly used in packaging applications.

On the other hand, blown film extrusion involves converting molten plastic into a bubble shape, which is then stretched into a tube. This method produces plastic films with a wide range of applications, including agriculture and packaging.

What is nano stretch film?

Nano-stretch films are made by a process called nanotechnology. During this process, extremely thin plastic sheets are made while maintaining durability and high strength. Nano-stretch films offer superior stretchability, load-holding capacity and puncture resistance. Such films securely wrap around and protect items during handling.